jaga compact hydronic fan coils

I am thrilled to announce jaga CLIMATE DESIGNERS, as our newest sponsor for theEnclosure.

As most of you know, I will be heating AND cooling, most of the dwelling, with a CEILING hydronic radiant panels (1st Hydronic Circuit Complete). This system comprises of Uponor PexA tubing snapped into ThermoFin U aluminium transfer plates from Radiant Design and Supply. Installation of this system went well (more details will follow on future post), but the extra effort required by the drywall crew (to not put a screw through the tubing on 6″ centres) is time consuming and expensive.

One of the rooms that is still unfinished, is the metal shop under the garage. This room is basically a concrete bunker, with concrete roof and floor, and NEXCHEM ICF walls.

The original plan was to put a small electric baseboard in this room, just to keep it from freezing, as it was not going to be conditioned. But then we had to put a RHEEM Prestige Hybrid Heat Pump Water Heater in this room when our plans to use an outdoor heat pump to create both the space conditioning, and potable hot water, fell through (really no good options for a combined systems operating at ultra-low supply temps). We found we had to switch to an indoor heat pump for domestic hot water, and this room was the only one big enough, and far enough from living space to isolate noise of unit, that could provide the air volume needed by the RHEEM heater.

This changed the use of the room, and now required it to not only conditioned, but also provide the estimated 3000Btu of energy needed by the heat pump at peak use. A plan was then made to include a large ceiling hydronic radiant panel, like the rest of the house, but trying to create a ‘hanging’ ceiling below the suspended slab above this room was going to be challenging (drilling anchors on a grid into the slab above and hanging some form of structure with threaded rod hangers). Also, having the ceiling heated would increase the temperature differential across the ceiling’s concrete slab, and increase the heat loss from the room.

I had been dreading this job, and knew it was going to be a long time before I started it and was able to complete it. In the meantime, I was going to have to use an inefficient, expensive to operate, 1500w electric heater to provide the required energy needed for the hot water production. I desperately wanted another solution.

So, I started researching wall mounted hydronic radiant panels, but I kept coming up against a road block. Because theEnclosure is so efficient, we will only be running a maximum supply water temperature of 85ºF (30ºC). This is very low, and to give you a comparison, the standard temp for in-floor radiant heating is 120ºF, and 140ºF to 160ºF is used for wall-mounted convectors. Repeatedly, I was told that at only 85ºF, I would have minimum heat output from that manufacturer’s panel.

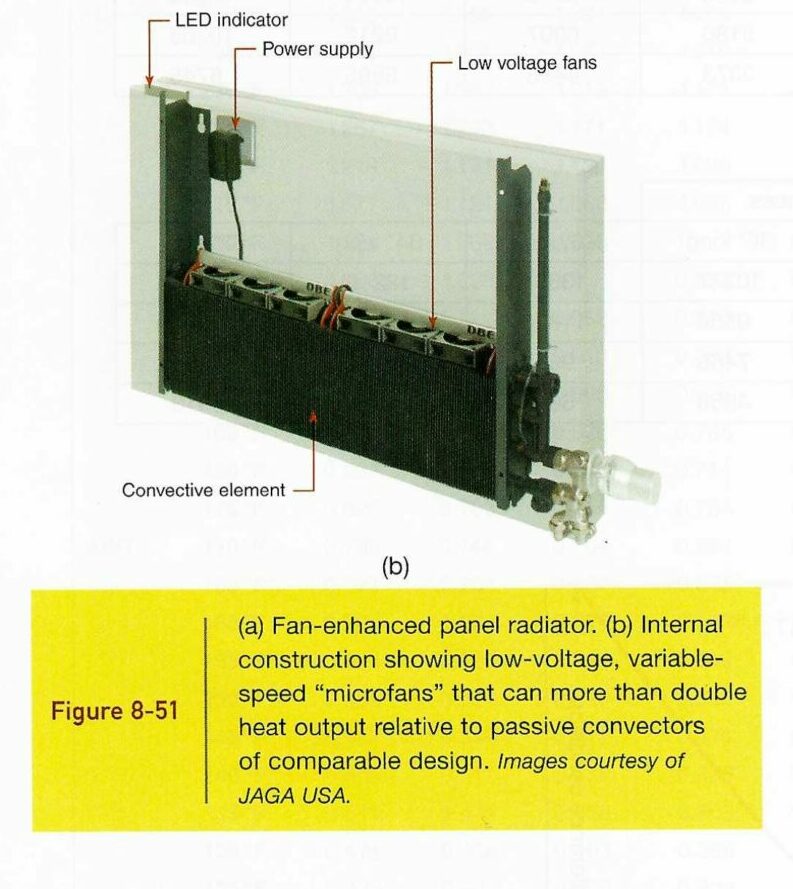

Fortunately, I have taken a few courses either by, or using texts by, John Siegenthaler. In his Modern Hydronic Heating text, he refers to a “state-of-the-art heat emitter that combines the function of a panel radiator and convector” with a photo of a jaga fan enhanced panel radiator.

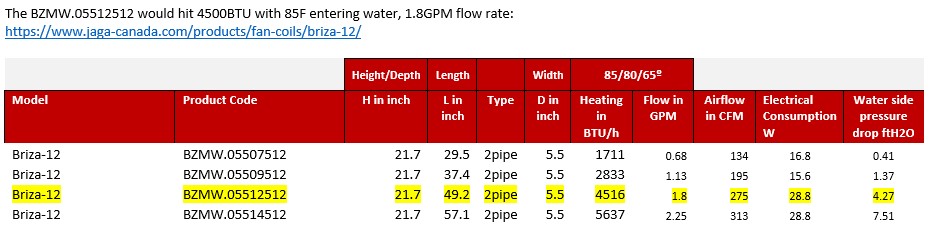

These units utilize a small EC ‘computer fans’ to move air across a hydronic coil to create very high efficiencies, even with ultra-low supply temperatures. Their Briza 12 2-pipe 21.7″ wide by 49.2″ high model creates a wopping 4516 BTU/h with 85ºF supply water. The unit can be mounted on a wall or a ceiling. I will initially mount mine on the upper half of a wall, but will transition to hanging it off the ceiling when I get around to finishing that room.

This is a huge relief, and cuts out probably a month of labour by myself and the drywall crew, and provides a solution now for a room I may not finish for years! The icing on the cake, is that jaga has graciously agreed to also be a supporter of theEnclosure, and have provided a partial sponsorship of their unit. Thank you Cyrus Kangarloo for your amazing support!

I am currently working through the installation of the mechanical room piping components you see laid out below (see Mechanical Room cam for current status). Unfortunately I am still waiting for some key components needed to finish the piping, including a Webstone 1-1/4 fill station 48615 . As of this morning, I switched suppliers (after waiting for 3-1/2 weeks for my order) and placed an order with a supplier who will be able to ship out of Calgary in the next day or so. In the meantime, I am also coming up to speed on the 224 wire terminations that are required to create the brains of this system (made a lot more complicated by the instrumentation I am adding to track the efficiency and energy consumption of the system). My thanks go out to Benoit at ThermAtlantic for his assistance in helping me navigate through this quagmire of wiring paths.

As always – thanks for visiting!

“The best way to pay for a lovely moment is to enjoy it.” — Richard David Bach (born 1936) Writer

“Every once in a while, a new technology, an old problem, and a big idea turn into an innovation.” —Dean Kamen (born 1951) American Engineer

Your blog pointing to a webpage and the URL is a 404 page.

Request you to please change the URL.

anchor text – ThermAtlantic

Old URL – https://thermatlantic.com/air-to-water-heat-pumps/residential-dx2w-modules/

Update the URL – https://thermatlantic.com/hydronic-cooling-options/hydronic-fan-coils/

Thanks Ben, sorry for late reply, was not notified of your message. I have updated but going to https://thermatlantic.com/dx2w-ex3-36-48-residential-air-to-water-module/ to highlight the DX2W