Steady Progress

I just love times where construction actually goes according to plan. They have been so few and far between in my experience, that when they do happen, it just makes life good.

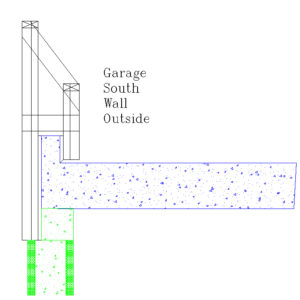

Such is the current situation with the garage slab forming. You may remember the below plan I drew up for the planned form work.

Well – it worked out perfectly! The forms were easy to construct, are sturdy (I can stand on them with next to no deflection), and should make the pouring of the curbs a piece of cake.

As above, I used a string line to identify the slope I needed for the garage slab. I then cut a series of plywood strips with the bottom edge chamfered (allows the concrete float to get tight into the corner for a nice finish). I temporarily hung the plywood strips so the bottom conformed to my slab slopping string line (bright orange). I then marked the top edge level with the upper string line and removed and cut the tapper before mounting permanently.

The result was a perfectly tapered plywood inboard form without the need to measure each segment. The cutting of these segments was made a breeze by the use of a guide rail for the skill saw. I got the idea when I came across this YouTube video. Mine took about 15 minutes to build using my construction table saw. I used a string line to ensure I had a perfectly straight fence as I screwed it to the base plate.

These are a great jig in construction as you can just screw then right to the workpiece to hold in place – No need for clamps. Below, I used to to cut a horizontal line on a vertical piece of plywood forming. The whole 18′ cut took about 2 minutes including the need to move the jig down to the next position on the line twice.

I also made a quick jig to cut ROCKWOOL insulation panels. I previously used a table saw but this needed to be done outdoors with a mask and the saw had to be cleaned up before I could cut wood again. The below jig took about 20 minutes to build and will cut all 3′ and 4′ panels in seconds.

I have a bit more of the scaffolding to remove from inside the room below the garage including the tower and sky bridge. I then need to rent some shoring that will be used to support the slab until it cures enough to self support. I have had some difficulties finding shoring as there is a LOT of commercial construction going on and many of the companies have a waiting list. But Kyle, my Lafarge salesman, came through with a suggestion to contact TTF Scaffolding. It looks like they will be able to help me. I need to come up with a list of materials needed once they tell me the length of their available beams and joists. Before delivering to site, I will also quickly form up the basement walk-up footing and install the required insulation. Then it will be a race to setup the shoring, install the reinforcing bar and then call for inspections.

Below is also a couple of photos showing ‘a better way’ for my gravel vertical drainage plane installation.

Thanks for visiting.

“You may encounter many defeats, but you must not be defeated. In fact, it may be necessary to encounter the defeats, so you can know who you are, what you can rise from, how you can still come out of it.” —Maya Angelou (1928-2014) Poet, Dancer, Producer, Playwright, Director, Author