Sub Slab Insulation - How to insulate around footings

I have had several of you asking “what’s up?” so here is an update. Not much 🙂

The tarp repair went as planned on Saturday and was completed in under 3 hours. The rest of the day was occupied with non-construction related tasks.

Monday was a full pull with both Brian from Embers and my father-in-law on site. Eric finished loading all of the 2×4 salvaged material into the new storage rack we had built on Friday. Brian and I had the thrilling job of moving enough of the ICF blocks from the road side to the bottom of the pit in order to make room for the floor truss package coming (I hope) from Quebec.

We built a chute to slide the blocks down to the bottom. It was my hope that we could slide multiple units down the chute and then go into the pit and unload. This would have allowed Brian to work on those while I worked on other things. I really was not up to lifting too much with the back problems I have had lately. Well – this did not work. It looked fine at first but when we went to remove the blocks we found the first two units had sheared apart. So I had to stay in the bottom of the pit and unload the blocks one unit at a time while Brian slid from above. And even then I had to devise ways to arrest some of the momentum before they hit the bottom to prevent damage. These blocks are durable, but fragile at the same time. They do not like sideways hits.

A much better method is to lower the skids into the pit with some form of crane which is exactly what I plan for the remaining 10 skids. I have rented a Bobcat E80 mini excavator for Monday AM. This has a 15′ dig depth so will allow me to perch at top of pit and dig out all of the soil I have stockpiled by the ramp as a result of digging the footing trenches and also scrapping away the mud before back-filling with gravel.

The timing of this rental coincides with when my truss package was supposed to be delivered from Quebec. I released the shipment on Monday and was told it would be here Tuesday with a 99% certainty. BUT as of today when I checked to confirm ETA, it had not left yet (waiting for explanation) – so it is looking very much like the second shipment out of the east is also going to be totally screwed up and I will have to hang onto the tractor for the full week’s rent compared to the 2 days I planned. This will cost me an extra $710 + tax. Oh well – it is just money – right 🙁

Because of the planned truss arrival timing, and the fact that I really cannot do more on site until I get the rest of the dirt out of the pit, I have not done too much more at the site this week. I took a couple of loads to the dump including my salvaged plastic pipe, and also picked up a 9ft W8x18 Metal I-Beam I need for the basement ceiling. I will use this as a flat edge to assembly my ICF into 3-block modules to be used for the first row that will be incorporated into the footings. This will take a bit more setup but will ensure a perfectly level and plumb ICF starter row making the rest of the installation so much easier.

The rest of the week has surrounded finalizing my footing design, including how I will insulate the interior strip and pad footings and the details surrounding the use of Fastfoot by Fab-Form (fabric footing forms that stop rising damp).

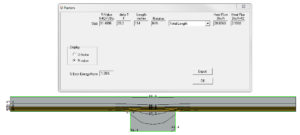

One issue is that I am trying to decide whether to sandwich the insulation between the footing and slab as in fig 1 or wrap the concrete assembly with insulation like figure 2 below. Based on THERM modeling, the method shown in figure 1 represent a bit better resistance to thermal flow but then requires the use of 100 PSI foam for a 14″ strip centered on the wall, and something with 300 PSI compression strength for directly under some post point loads, whereas the fig 2 method can utilize 60 PSI foam on the bottom of the footing and 20 PSI everywhere else.

If you have an opinion on this issue (or anything else I write on) please drop me a message and chime in. Would love to get others input and experience on this.

As I have had some time this week, I have been cleaning up paperwork and updating my to-do list. I also have approached two new vendors for possible sponsorship for the project. This led to a visit of the hits stats for my blog and I was totally shocked at the result. For most of the last year the blog had averaged 500 or so hits a month now that most of my activity was focused on this journal (down from 750-800 hits when the blog was my main activity). I expected this to continue or even drop as I concentrated more on this site than the blog, but I was blow away to see that for the last month it was 1901 hits and that I was rapidly approaching 18,000 all time hits. This is very humbling and definitely helps provide incentive to stay the course.

All I can say is Thank You for Visiting!

It really seems like an easier job than I thought to insulate around footings after reading this article. It seems like you worked pretty hard for three hours, but when thinking back, it didn’t take as long as other jobs. We’re thinking about getting our insulation done in our attic. Doesn’t it help with keeping the energy bill down too?

http://www.biosenv.com/bios-energy-services/insulation/

FelicitySandy Yes the attic would be at the top of the list of importance. As this is going to be a high performing very efficient dwelling, we are looking after all the major thermal bridges but also looking at some of these minor ones to wring out every bit of efficiency that is possible/prudent.